|

History of TS Plzen

|

|

|

TS Plzen is a successor company of the huge Skoda

concern which split into numerous specialized companies after the

fall of communism in 1990. (However, physically all these successor

companies continue to be located in the same place, in the city

of Plzen around the Tylova Street within the compounds of the industrial

complex of Skoda).The history of TS Plzen and of Skoda reaches back

to mid 19th century.

|

|

|

|

|

In 1859,

Count Wallenstein-Vartenberk set up a branch of his foundry and engineering

works in Plzeň. The output of the plant, employing over a hundred

workers, included machinery and equipment for sugar mills, breweries,

mines, steam engines, boilers, iron bridge structures, and railway

facilities. In 1869, the plant was taken over by Emil Škoda, an industrious

engineer and dynamic entrepreneur.

<-- Emil Škoda (1839 - 1900), founder of the Škoda Works in Plzeň

|

|

|

Škoda was quick to

expand business, and in the 1880s founded what was then a very modern

steelworks capable of delivering castings weighing dozens of tons.

Steel castings and, later, forgings for larger passenger liners and

warships went on to rank alongside the sugar mills as the top export

branches of Škoda's factory.

<-- Casting of the rudder frame for the

Japanese warship Mikasa (1900)

|

|

In 1899,

the ever expanding business was transformed into a joint-stock company,

and before the First World War Škoda Works became the largest arms

manufacturer in Austria-Hungary. It was a navy and army contractor,

mainly supplying heavy guns and ammunition.

<-- Guns for the Austro-Hungarian navy (1904)

|

|

Exports

included castings, such as part of the piping for the Niagara Falls

Power Plant or for the Suez Canal sluices, as well as machinery for

sugar mills in Turkey, breweries throughout Europe, and guns for the

Far East and South America.

m

<-- Casting of part of the piping for

the Niagara Falls Power Station (1905)

|

|

The First World War

brought a drop in the output of peacetime products. Huge sums were

invested into expanding production capacities. By this time, Škoda

Works already held a majorities in a number of companies in the Czech

Lands and abroad that were not involved in arms manufacture. In 1917,

the company had 35,000 employees in Plzeň alone.

<-- 380 mm calibre mortar in firing position (1916)

|

|

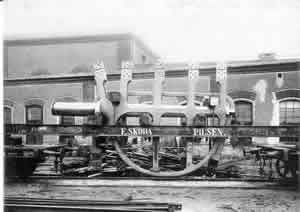

Following the emergence

of the Czecho-Slovak Republic in 1918, in the complex economic conditions

of post-war Europe the company was transformed from what was exclusively

an arms manufacturer into a multi-sector concern. In addition to traditional

branches, the production programme embraced a number of new concepts,

such as steam (and later electric) locomotives...

<-- Locomotives for Romania State Railways

(1921)

|

|

...freight and passenger

vehicles...

|

|

|

|

|

The luxury ŠKODA - HISPANO

SUIZA for President T.G.

Masaryk (1926)

|

|

|

ŠKODA 606

truck in Iran (1936) |

|

|

|

|

...aircraft, ships, machine

tools, steam turbines, power-engineering equipment, etc.

|

|

|

|

|

Casting of the rudder

frame for

the French passenger

ship Normandie (1933) |

|

Turboset at Ervěnice

Power

Station (1929) |

In 1923, the company's world-famous registered trademark

- the winged arrow in a circle - was entered in the Companies Register.

The deteriorating political situation in Europe saw arms production

rise again in the mid-thirties.

|

|

|

|

|

AVIA B 534 fighter

plane for

the Czechoslovak Army (1933) |

|

150 mm calibre

howitzer 16/19 (1934) |

The

Second World War and the company's forced integration into the German

weapons programme led to serious damage at the Works themselves (70%

of the company complex was destroyed by Allied bombing in April 1945)

and the loss of several foreign markets. The

Second World War and the company's forced integration into the German

weapons programme led to serious damage at the Works themselves (70%

of the company complex was destroyed by Allied bombing in April 1945)

and the loss of several foreign markets.

<-- Škoda Works after the bombing raid

of 25 April 1945.

|

|

In 1945, the company was nationalized.

Škoda Works was gradually split up into different sections (e.g. the

car works in Mladá Boleslav, the aircraft plant in Prague, factories

in Slovakia, and other plants producing food-industry equipment).

The company's main task now was to produce equipment for heavy engineering,

capital construction in the industrial sector, public transportation,

and power engineering. Most exports were headed towards the Eastern

Bloc.

|

|

|

|

|

|

|

|

|

|

Electric locomotive capable

of

8,000 KW output and a speed of

200 kph, built for the USSR (1977)

|

|

Mělník III Thermal Power Station,

with a 500 MW turboset (1981)

|

|

|

|

|

|

|

|

The ŠKODA WD 200

horizontal drilling and

milling machine won the

Grand Prix at Expo 58

in Brussels

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Following the change in political climate in 1989,

ŠKODA started along the path of privatization, and used this time

to come up with an optimal production programme, make new business

contacts, and look for markets other than those that had so far been

its priority (and only) markets, i.e. the Comecon countries and the

Soviet Union, which collapsed after 1989.

|

|

|

|

|

14 Tr E trolley-bus

for urban

transportation in Dayton, Ohio (1996) |

|

Astra low-floor

tram (1997)

|

In 1992, the company was privatized by the

so-called Czech method. It began expanding its production activities

(e.g. by acquiring the TATRA and LIAZ vehicle works and constructing

a plant to produce aluminium drinks cans). This expansion put the

company's financial stability in jeopardy. In 1999, it concluded a

standstill agreement with its main creditor banks, and restructuring

of the entire capital structure of the Škoda group was launched. The

result was legal and financial stability at the company. Now the sectoral

restructuring of the production companies in the group is under way.

In April 2000, ŠKODA HOLDING a.s. took over at the helm, controlling

primary nineteen subsidiaries and most product lines.

|

|