|

|

|

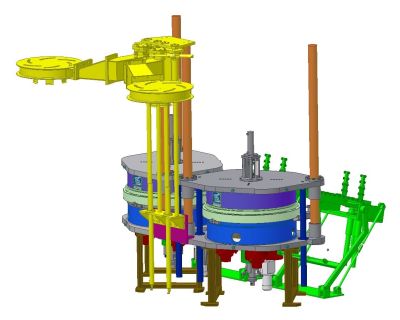

Curing presses - Production Programme

|

For more than 40 years

TS Plzeņ , the successor of Skoda heavy machinery division has been

supplying tyre curing presses mainly for the production of tyres for

trucks, tractors and building machines.

Tradition, many-year experience and knowledge of rubber technologies

- these are the principal factors that make TS Plzeņ capable to assure

the top level of its tyre curing presses. |

|

The production program of TS Plzen includes:

|

Hydraulic tire curing

presses

- Two-chambers model, sizes from 63,5" up to 75"

- One-chamber model, sizes from 75" up to 130"

- For forming radial and diagonal tyres with natural, synthetic

or steel cords

- Equipped with heating platens and fully automatic tire

loaders and unloaders

- Modern HVML concept

|

Hydraulic radial

presses

- Double-chamber, RVL press, size 66"

- B-O-M system

- Designed for radial tyres in segment moulds.

- Outer heating of moulds by steam heating platens along

with steam supply to the outer circuit of segment mould

- Modern RVL concept

|

|

Mechanical

curing presses

- Two-chambers model, size 63,5"

- One-chamber model, sizes 75" to 130"

- For forming radial and diagonal tyres with natural, synthetic

or steel cords

- Two versions: with steam dome or with heating platen

- Equipped with automatic tire loaders and unloaders

|

Modernization

& overhaul rebuild

- Refurbished press has parameters comparable to those of

brand new press

- High control accuracy of technological parameters

- Substantially lower cost compared to price of new press

- Know-how and experience in curing presses

|

|

|

|

|

|